On the one hand, it is the fugitive leader in the packaging business; on the other hand, it has a broad scope of regular plastic applications. Polystyrene can be ordinarily transparent but can be colored with colorants.

Polystyrene is generally injection molded, vacuum formed, or extruded, while expanded polystyrene is either extruded or molded in a special method.

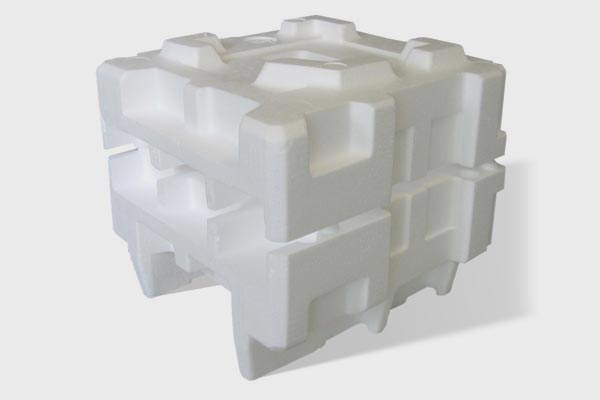

Three main types of polystyrene include polystyrene foam, general polystyrene plastic, and polystyrene film. Amongst the diverse kinds of foam are expanded polystyrene (EPS) and extruded polystyrene (XPS). EPS involves the most well-known and popular types of polystyrene to contain Styrofoam and packing.

General Purpose Polystyrene (GPPS) and High Impact Polystyrene (HIPS) are presumably the most generally used PS resins for injection molding. GPPS is transparent but fragile (think of a CD jewel case) while HIPS is opaque and much less fragile.

Polystyrene also is formed into a foam material named expanded polystyrene (EPS) or extruded polystyrene (XPS), which is valued for its insulating and cushioning features.

Types of Polystyrene:

- EPS

- GPPS

- HIPS

Why choose us:

With over two decades of practical experience in international business and strong supply networks, Romak Trading team facilitates a successful supply process.

We at Romak Trading team can supply world-class petrochemical products while we organize customized logistic services.

For more information, contact us at Info@romaktrading.com.

© Copyright 2021 by ROMAK Trading Co. All Rights Reserved.