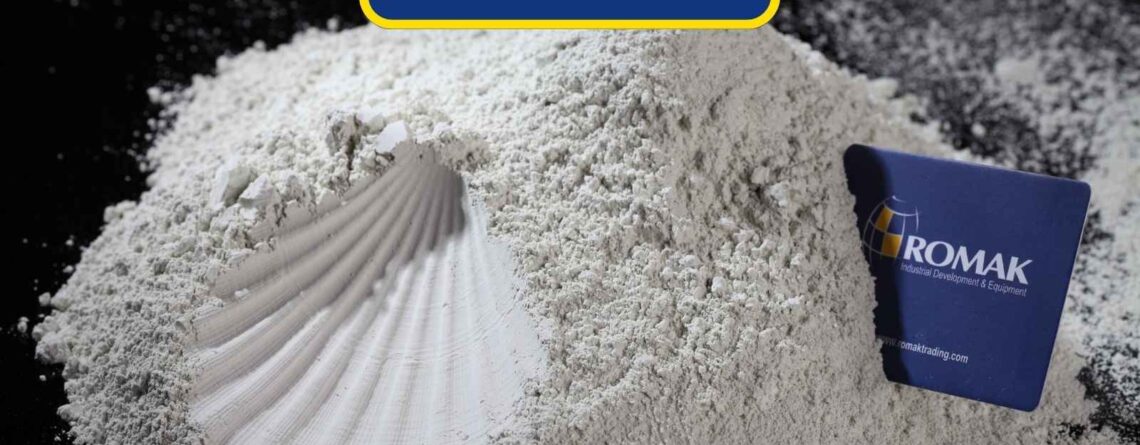

Iran White Cement Supplier with Competitive Export Prices

Understanding the Global Demand for White Cement White cement has long been a cornerstone in architectural, decorative, and infrastructure projects, prized for its brilliant color, high reflectivity, and consistent strength. As global construction standards evolve and urban aesthetics gain importance, demand for this specialized cement continues to rise. For buyers and importers seeking quality, reliability,...