A guide to Iran HDPE

High density polyethylene (HDPE) is the most used of the three polyethylene’s for a wide range of applications. Iran is one of the lead producers and has established its place in the market.

Here we will introduce Iran HDPE and discuss the market and price of it.

HDPE is a thermoplastic polyethylene. It has a linear structure with no or low degree of branching. It is produced majorly using two techniques: Slurry Polymerization or Gas Phase Polymerization.

Manufactured at low temperatures of between 70 to 300 °C and pressures of 10-80 bar, the density of HDPE ranges from 930 to 970 kg/m3.

The linear structure and high density of this polyethylene provide high crystallinity and thus high tensile strength, especially compared to other types of polyethylene.

Some of the different properties of HDPE are as following:

- Relatively stiff material with useful temperature capabilities

- Low cost polymer with good processability

- Good low temperature resistance

- Good toughness at low temperatures

- Excellent electrical insulating properties

- Deficient water absorption

- Excellent resistance to most solvents

- Excellent resistance to alcohols, dilute acids, and alkalis

- Moderate resistance to oils and greases

- Poor resistance to hydrocarbons (aliphatic, aromatic, halogenated)

HDPE’s resin identification code is 2, which is branded on most of the products produced from it.

Although it has some excellent properties, there are some disadvantages to HDPE. Some of them are:

- Susceptible to stress cracking

- Lower stiffness than polypropylene

- High mold shrinkage

- Insufficient UV and low heat resistance

- High-frequency welding and joining impossible

Grades of Iran HDPE

High density polyethylene is produced in various grades in Iran to meet customer requirements. These grades are:

- Film

- Injection molding

- Roto molding

- Monofilament

- Yarn and caps and closure

According to the applications of each grade, certain additives are included in the grades.

These additives include antioxidants process stabilization, antilock compounds to reduce sticking of adjacent film layers and slip agents to reduce friction.

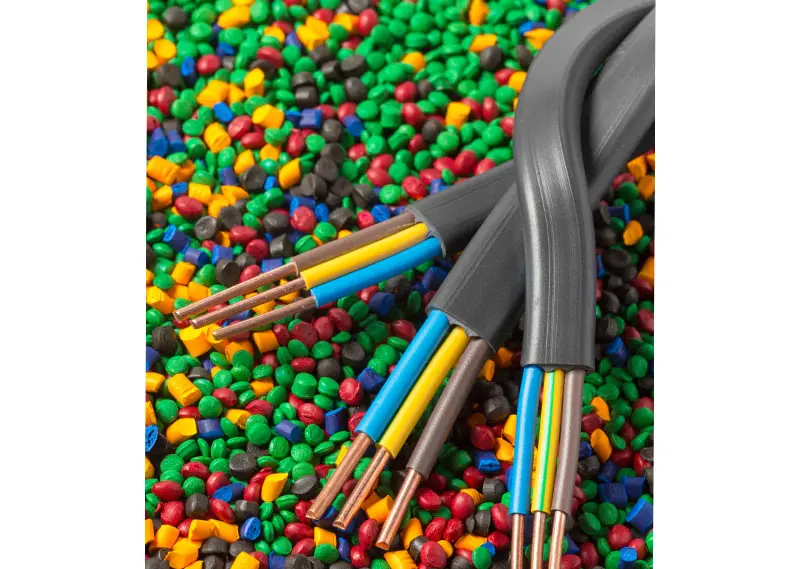

These grades are provided in the form of granules.

Producing them in the form of powder from some manufacturers is also possible. Iran HDPE grades are produced according to global standards and can compete or even best their international competition.

Applications of Iran HDPE

HDPE is an ideal material for various applications across industries because of its excellent combination of properties. It can also be engineered according to the end use requirements.

Some of the major applications include:

- Packaging Applications: HDPE is used in multiple packaging applications, including crates, trays, liquid storage bottles, caps for food packaging, drums, industrial bulk containers, and so on. In such applications, HDPE provides a suitable impact strength for the end use, and also, it won’t leach into the bottles’ contents. It is also recyclable, making it an excellent option for these highly disposable products.

- Pipes and Fittings: pipes for gas, water, sewage, drainage, industrial application, cable protection, steel pipe coating, large inspection chambers, and utility holes for pipe sewage can be manufactured from HDPE due to its excellent resistance to chemical and hydrolysis. So HDPE pipe properties are sufficient for different usages.

- Fibers and Textiles: HDPE is widely used in the production of ropes, fishing, sports nets, nets for agricultural use, Industrial and decorative fabrics due to its high tensile strength.

Some of the other applications include:

- Automotive containers

- Wiring and cables

- 3D printer filament

- Geomembrane for hydraulic applications

- Plastic surgery (skeletal and facial reconstruction)

- Stone paper production

Recycled HDPE has proven almost as versatile and popular as the virgin material. It is used in many of the same applications noted above.

The price of Iran HDPE and the factors affecting it

Since almost all polymer feedstocks are derived from crude oil or natural gas, their prices and the changes in their prices are the key factors determining the cost of polymers.

Thus, the price volatility of crude oil directly impacts the overall market growth. Another factor is the relation between the price of crude oil and natural gas in Asian economies, which further influences the price of polymeric material.

As the demand for crude oil and natural gas increases and the supply shortens, the price of polymeric material increases and a decrease in the price happens when supply is high and demand is low. So HDPE market price is influenced by a lot of items.

Iran, with 21.7 thousand million tonnes (9.3 % share of total), has the fourth largest oil reserves after Venezuela (with 17.5 % share of total), Saudi Arabi (15.7 % share of total), and Canada (10.2 % share of total), while its share from the world’s total oil production is only 4.0 %. On the other hand, Iran, with 34.0 trillion cubic meters (18.2 % share of total) of natural gas, has the world’s second largest natural gas reserves in the world.

With these vast resources of oil and gas, Iran is one of the leading members of OPEC (Organization of Petroleum Exporting Countries) and the Organization of Gas Exporting Countries (GECF)

According to the Oil Ministry’s news portal, $14.5 billion has been generated from its sale, with 23 million tons exported to international markets, generating $9.5 billion in revenue.

A reduction in crude oil prices has been happening in the recent year, causing a decrease in the price of various grades of Iran HDPE. But the price of crude oil and demand for HDPE has been increasing.

This has led to a rise in the price of Iran HDPE. Constant monitoring of its market and prices in order to avoid any negative impacts on the business is of crucial importance.

The market of Iran HDPE and the factors affecting it

The global HDPE market is anticipated to show substantial growth during the forecast period. The growing demand for high performance polymers across various industry verticals is set to drive growth throughout the 2016-2024 period with a CAGR of over 4% per year. Fluctuating crude oil prices is anticipated to be a significant downside to the growth of the global market.

On the other hand, an increase in the usage of plastic pipes as substituents and robust demand from the packaging industry is the main reason for the Iran HDPE market’s growth. It now has the largest polyethylene market, with LLDPE following close by.

At present, there are 17 polyolefin manufacturing units which are spread in different regions in Iran, providing various grades of HDPE with properties conformable to international standards at reasonable prices compared to other countries.

According to trade statistics of 105 countries, the UN’s International trade statistics have reported that in 2017, Iran, with 7.21% of the worldwide HDPE export (1.92% of Iran’s total exports), is the third largest HDPE supplier in the world and has provided material for 56 countries across the globe. These statistics prove Iran as a very desirable HDPE supplier in the global market.

Romak Trading Company: a promising name in the Iran HDPE market

Here at Romak Trading Company, we strive to provide high quality Iran HDPE grades with the most reasonable prices to our customers from across the globe.

We are one of the prominent trading companies supporting the Iran HDPE market. With our close connection with top quality Iran HDPE suppliers, manufacturers, and petrochemical companies, we are able to provide any considerable quantity of various grades in any desired form and packaging.

Iran HDPE grades can be provided in the form of granule or powder, and the packaging of them can be in 25 Kg bags or 500-2500 Kg jumbo bags, according to the customer’s requirements.

Leave a Reply

You must be logged in to post a comment.