Iran is a well-known supplier of bentonite in the Middle East. Using bentonite has a long history in Iran, and Iran bentonite has been used as a cleaner and cure during the centuries.

Iranian suppliers render their products and services to local and international traders. The Iranian exporters of bentonite trade it to more than 20 countries.

Bentonite is a mineral product structured from Alumina and Silica sheets.

While it can divide into particles with 0.003-micrometer dimension and 0.01-micrometer longitude. Therefore, easy separation and negative electrical charge result in rapid distribution of bentonite in water.

Besides, having high ion exchange capacity is one of the most significant characteristics of this mineral; Which has an obvious effect on bentonite’s classification as a tradable product.

Iran is one of the richest countries located in the heart of MENA regions; Both in Calcium bentonite and Sodium bentonite. Sodium bentonite has a very high swelling capacity; As far as we mostly know it as Swelling bentonite.

The exclusive water absorption of sodium bentonite makes it a very efficacious material for construction and excavation. Though, Calcium bentonite has a lower swelling potential.

Supply and Export Iran Bentonite

The casting process with green sand is expected to increase extremely in the coming years. Therefore, bentonite will turn into a key product in business.

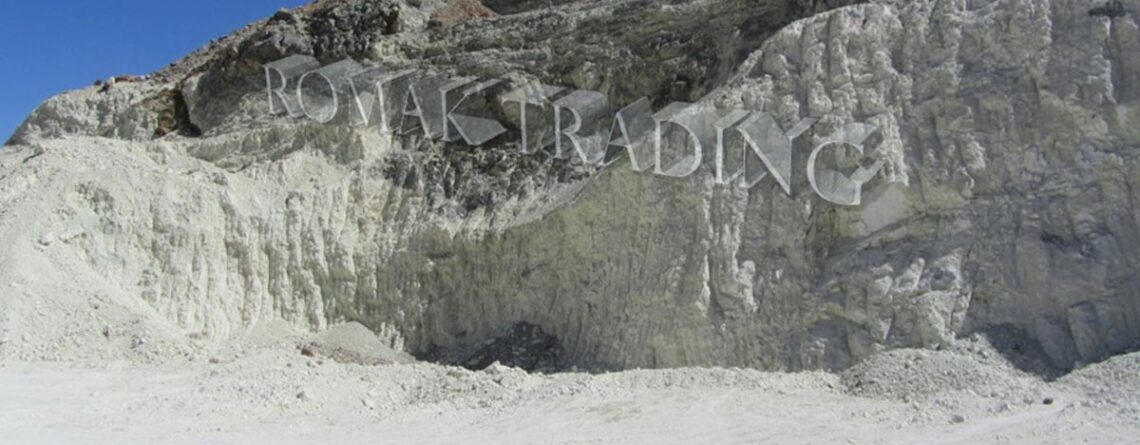

Particularly, the experts, expect bentonite’s growth in supply and demand in MENA regions and the Asia Pacific. So, Romak Trading as an experienced company in bentonite supply and export is active in this field. Our reliable and professional logistic team delivers cargoes to different ports all over the world.

The Iranian suppliers of bentonite, supply the high quality of bentonite to Persian Gulf countries and far destinations. Furthermore, these suppliers trade the bentonite in raw and processing form; and provide it in different qualities and shapes to export.

Iran Drilling bentonite

Best-grade Iran Drilling Bentonite (sodium montmorillonite), which is mainly used as a filter cake control agent and suspension agent, is the suspension agent in freshwater systems and is used in all water-based gas systems.

Bentonite is used as a lubricant/ thickener for drilling fluids. Drilling mud is very important in removing drilling cuttings during the drilling process. When bentonite is mixed with water, it forms a liquid (slurry) that is pumped through the drill stem and exits through the drill head. Drilling mud or gel is used for both cooling and lubrication of the drill bit. It also seals the drill hole and prevents leakage and prevents the walls of the well from collapsing.

Characteristics

Iran Drilling Bentonite is used as an additive in drilling fluids worldwide. Its main function is the viscosity of the mud to reduce fluid loss. High-quality bentonite should be composed of montmorillonite, mainly.

In practice, bentonites often contain significant amounts of other minerals such as illite, kaolinite, chlorite, and non-clay components such as quartz and feldspar. Since montmorillonite clays have the highest swelling capacity (which causes viscosity and low permeability of the filter cake), the presence of other materials will negatively affect the quality of bentonite. The type of exchangeable ions has a large effect on the swelling capacity of Montmorillonite. So far, the best performance is obtained from sodium montmorillonite.

Additives

If the mineral composition of Bentonite contains insufficient viscosity, various additives should be added. This additive can be salt or a polymer that increases the quality of the liquid by slightly increasing the clotting of the suspended bentonite. It has been shown that an adequate amount of sodium is required to obtain a well-dispersed bentonite suspension.

It has also been proven that the physical properties of bentonites are affected by the Na/Ca ratio and bentonite swelling is improved by adding sodium carbonate. In practice, magnesium oxide is usually used to increase the strength of the gel.

Different types of chemicals and polymers are used in the production of drilling mud to achieve some functional properties such as proper flow rheology, density, mud activity, and fluid loss control. The choice of additives should be based on technical and environmental factors. Modified polyacrylamide and starch are often used for the early stages of drilling to depths where the temperature is 150 ° C at the end of the cavity.

Function

As Iran Drilling Bentonite is released into the water, relatively large shells of sodium bentonite are converted into colloidal particles, releasing electrical energy stored in the crystal lattice and swell about 15 to 30 times the original volume. This property is used in drilling to disperse heavy materials; thus, bentonite creates a coating on the good wall and prevents the migration of oil and gas, and stabilizes the wall.

Features and properties (API Grade; 13A-section 9)

This material must be in powder form and free of visible impurities.

Humidity: maximum 12% at 105±2 ˚C

Yield: minimum 16

Plastic viscosity 600 Reading at 64 grams: minimum 30

Yield Point/plastic viscosity ratio: maximum 3

Volume Filter: maximum 15 ml

Particle size 200 mesh.

Advantages

- Hydrates more than other types of clays

- Best for generating viscosity, developing gels for suspension, and controlling filtration

- Small particle size, unique flat shape, and high surface area of hydrated Bentonite viscosity

- Provides superior filtration characteristics

- Promotes the deposition of thin and compressible filter cakes in the wellbore

Particularly, the experts, expect bentonite’s growth in supply and demand in MENA regions and the Asia Pacific. So, Romak Trading as an experienced company in bentonite supply and export is active in this field. Our reliable and professional logistic team delivers cargoes to different ports all over the world.

Leave a Reply

You must be logged in to post a comment.