As global steelmaking shifts toward cleaner and more efficient technologies, Direct Reduced Iron (DRI) has become an indispensable raw material for electric arc furnaces (EAFs). Among leading suppliers, Iran DRI export logistics have earned global attention thanks to the country’s abundant natural gas resources, consistent metallurgical quality, and expanding port infrastructure. In this article, we explore the end-to-end Iran DRI export logistics process, including packaging options, transport methods, and compliance considerations — all tailored to meet the needs of international buyers who are serious about sourcing DRI at scale.

Why Global Buyers Prefer Iran DRI

Steel producers across Asia, Europe, and Africa are constantly seeking reliable DRI sources to maintain operational continuity and minimize costs. What has placed Iran DRI on the global map is not just the volume of its production but the strategic advantages it brings.

With decades of industrial expertise and a vertically integrated supply chain, Iran DRI suppliers offer highly metallized DRI (often above 92%) that’s remarkably uniform in composition. This ensures better furnace efficiency and lower slag generation during melting. Additionally, Iranian plants enjoy direct access to natural gas, making the DRI production process both cost-effective and environmentally cleaner than coke-based alternatives.

On a personal note, one of our longtime clients — a steel mill in Turkey — shared that shifting to Iran DRI with a reliable supplier (Romak Trading) helped them reduce furnace downtime due to fewer contaminants and higher metallization. Their words? “The product is consistent, and the logistics flow smoother than expected.”

Overview of Iran DRI Export Process

1. Source and Supply

2. Export Ports

Packaging Options for Exported Iran DRI

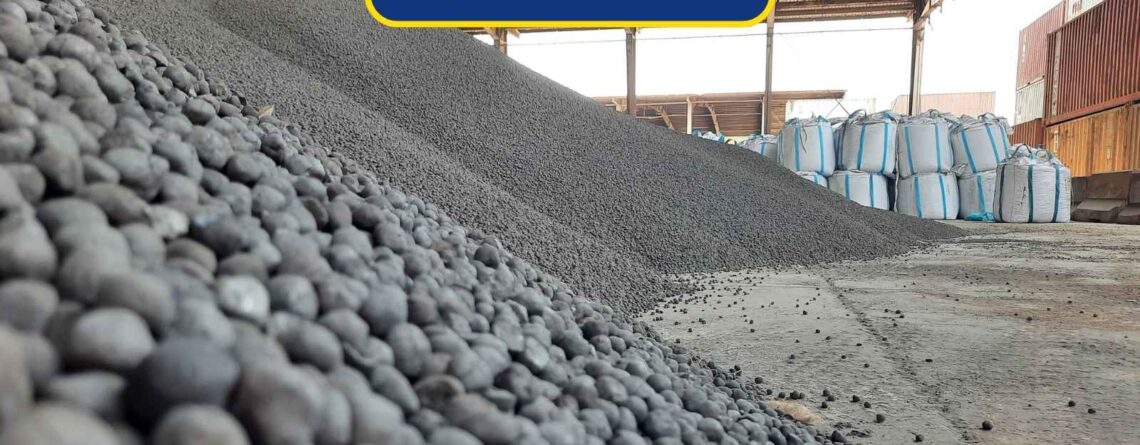

Bulk Shipments

Jumbo Bags (1–1.2 MT Capacity)

Shipping Methods: Containerized vs. Break Bulk

Containerized Shipping

Break Bulk Cargo

Critical Considerations for Iran DRI Export Logistics

- Product Stability: Cold DRI is prone to oxidation. Consider passivated material or request HBI for long-distance shipments.

- Documentation: Ensure correct HS codes (usually 7203) and follow IMDG Code regulations. All packaging must include proper labeling regarding material risks and handling instructions.

- Inspection and Certification: Reputable Iran DRI traders provide SGS or equivalent third-party inspection reports, chemical analyses, and origin certificates as part of their standard offering.

- Incoterms: Most buyers prefer FOB or CFR terms.

Best Practices for DRI Importers

- Select the Right Packaging: Match the volume of your order with the most secure packaging method. Jumbo bags are ideal for moderate volumes; bulk shipping works best for large, nearby buyers.

- Plan for Unloading: Coordinate with destination ports to ensure proper unloading facilities are available. Some ports are not equipped to handle bulk DRI.

- Work with Reliable Partners: Choose a proven Iran DRI supplier with a track record of successful international shipments. They should be able to support you with flexible packaging, fast lead times, and clear documentation.

Conclusion: The Future of Iran DRI Export Logistics

As the global demand for steel continues to rise, DRI will remain a key raw material in the transition to greener production. And with its growing export infrastructure, stable product quality, and flexible packaging options, Iran is well-positioned to serve that demand. Whether you’re a large-scale mill or a regional trader, understanding Iran DRI export logistics helps you reduce risk, improve efficiency, and plan smarter.

If you’re looking for a trusted Iran DRI supplier, Iran DRI exporter, or experienced Iran DRI trader, it’s essential to choose a partner who understands not just the material — but the logistics that move it.

Leave a Reply

You must be logged in to post a comment.