Introduction

Direct Reduced Iron (DRI) has become a cornerstone in modern steelmaking, offering significant advantages in terms of purity, consistency, and reduced carbon footprint. However, ensuring the quality of Iran DRI is crucial for buyers, traders, and manufacturers who rely on this material for efficient steel production. Understanding the quality indicators and verification processes can significantly impact your bottom line and operational efficiency. Here’s a comprehensive guide to verifying the Iran DRI quality standards, whether you’re an experienced Iran DRI supplier or a buyer looking for reliable sources.

Key Quality Indicators for Iran DRI

1. Chemical Composition

Chemical composition is the most critical factor in determining the Iran DRI quality standards. High-grade Iran DRI should have a high iron content (typically above 90%) with minimal impurities like phosphorus, sulfur, and gangue material, which can negatively impact the final steel quality. For instance, high sulfur levels can lead to brittleness, while excessive phosphorus can weaken the final product’s structural integrity.

- Iron Content (Fe): The primary component, usually above 90%, which directly impacts the strength and ductility of the produced steel.

- Carbon and Sulfur Levels: These should be kept within controlled limits to avoid issues like brittleness or poor weldability in the final steel.

- Metallic Iron (Fe°): This refers to the proportion of iron present in its pure, metallic form, which is essential for efficient steelmaking.

Romak Trading's DRI Chemical Analysis :

2. Physical Properties

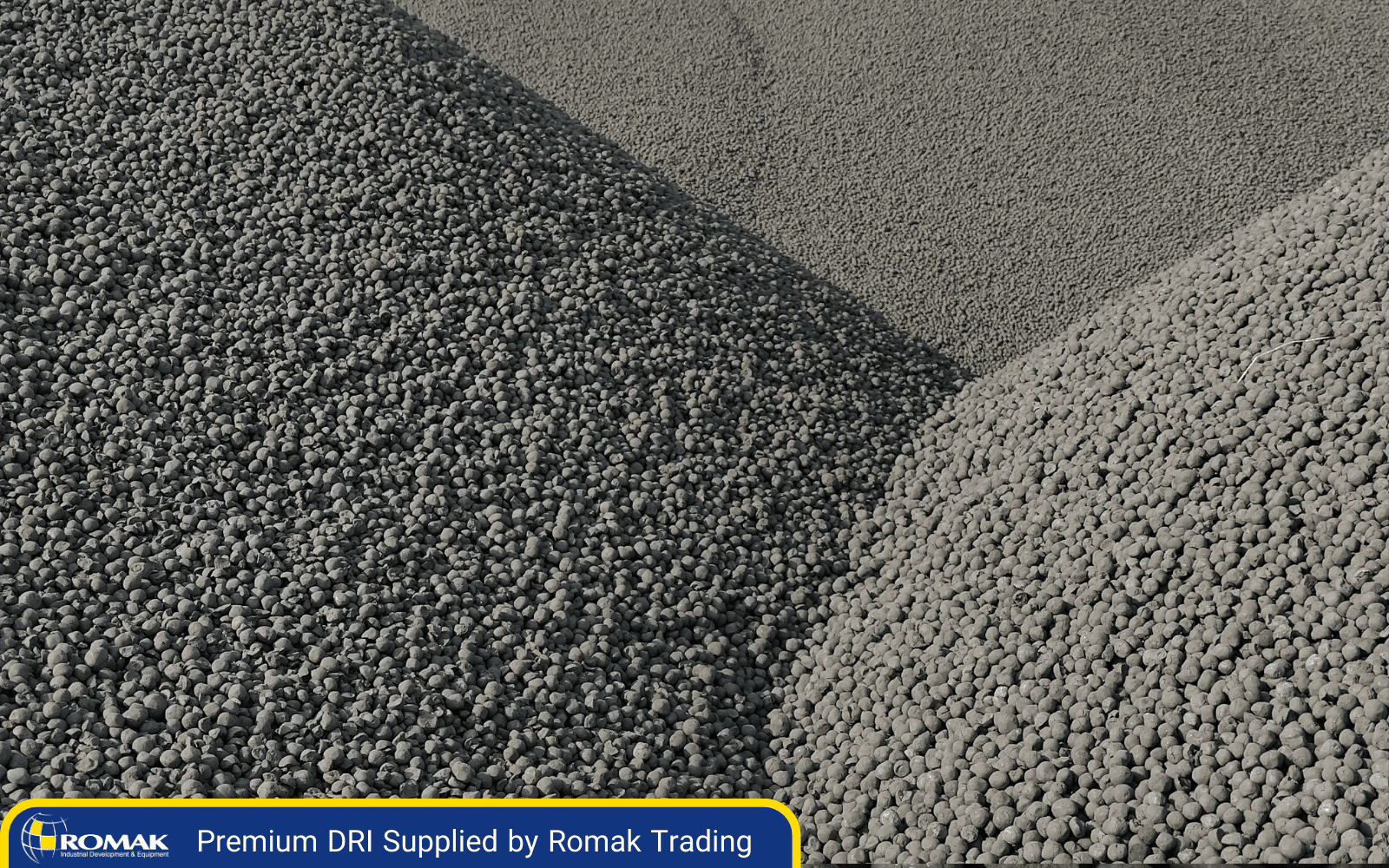

Physical characteristics play a significant role in the handling, transportation, and performance of Iran DRI. For example, a shipment of Iran DRI with inconsistent particle size distribution can lead to uneven melting, affecting production efficiency.

- Bulk Density: Indicates the mass per unit volume, affecting transport costs and furnace efficiency.

- Particle Size Distribution: Consistency in size leads to uniform melting and reduces clogging in furnaces.

- Porosity and Shape: Higher porosity can lead to faster oxidation but also improves reactivity in the furnace.

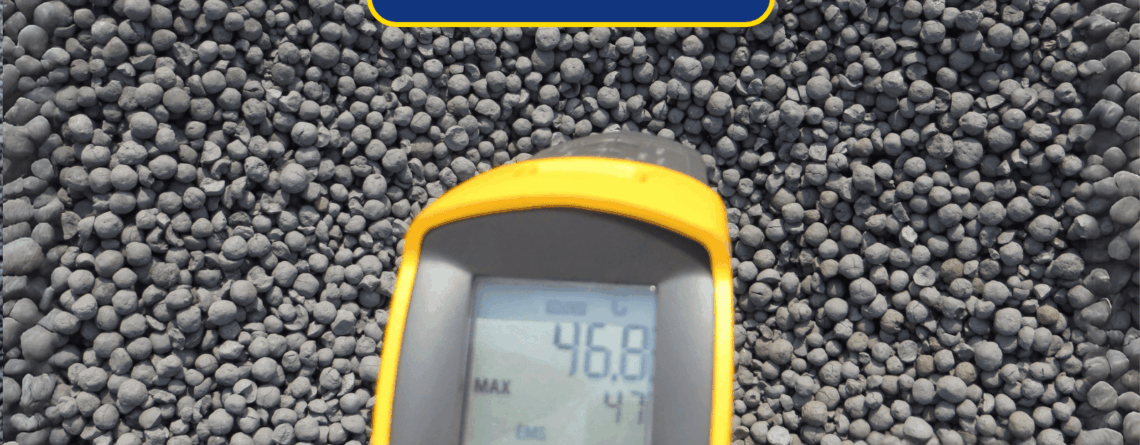

Romak Trading's DRI Physical Analysis :

3. Metallurgical Properties

Understanding the metallurgical properties of Iran DRI is essential for meeting Iran DRI quality standards. This includes the degree of metallization, which measures the amount of iron present as metallic iron rather than oxides.

- Degree of Metallization: Indicates the ratio of metallic iron to total iron, directly impacting the yield of steel production.

- Cold Crushing Strength (CCS): A measure of the physical toughness of Iran DRI pellets or briquettes, crucial for handling and transport.

- Reactivity: High reactivity can lead to faster processing times but also increases the risk of oxidation during storage.

Testing and Certification Standards

1. Laboratory Testing Methods

Quality verification often begins in the lab, where precise measurements are taken to assess chemical composition, physical structure, and metallurgical properties.

- X-Ray Fluorescence (XRF): Used for rapid chemical analysis to determine the elemental composition.

- Thermogravimetric Analysis (TGA): Measures changes in weight as the sample is heated, providing insights into moisture content and impurities.

- Microstructure Analysis: Examines the internal structure of Iran DRI to identify impurities and structural weaknesses.

2. International Standards for Iran DRI

Quality verification often begins in the lab, where precise measurements are taken to assess chemical composition, physical structure, and metallurgical properties.

- X-Ray Fluorescence (XRF): Used for rapid chemical analysis to determine the elemental composition.

- Thermogravimetric Analysis (TGA): Measures changes in weight as the sample is heated, providing insights into moisture content and impurities.

- Microstructure Analysis: Examines the internal structure of Iran DRI to identify impurities and structural weaknesses.

3. Importance of Third-Party Verification

Quality Control During Production

1. Raw Material Selection and Processing

2. Continuous Quality Monitoring

3. Packaging and Handling Precautions

Supplier Reputation and Track Record

Buyer’s Checklist for Quality Verification

- Review product specifications and test certificates.

- Request samples for independent testing before placing large orders.

- Evaluate Iran DRI supplier certifications and past performance to ensure consistent quality.

Conclusion

For more insights on sourcing premium Iran DRI, consider reaching out to reputable suppliers who can provide verified, high-quality materials for your production needs.

Leave a Reply

You must be logged in to post a comment.